Fullbox transforms fragmented, paper-heavy processes into a unified digital command center that drives compliance, improves readiness, and saves countless hours of administrative work.

When information is trapped in filing cabinets, spreadsheets, and disconnected systems, your department can't leverage its full value. Fullbox creates a single source of truth that empowers better decisions, faster response, and complete readiness.

One Platform. Five Powerful Modules.

Equipment Management

Every piece of PPE tracked from purchase to retirement, with automatic compliance monitoring for NFPA 1851, 1971, and 1977 standards. No more missed inspections or surprise non-compliance discoveries.

⦁ Complete Lifecycle Tracking: Purchase records, inspection history, maintenance logs, and retirement forecasting all in one place⦁ Assignment Management: Know exactly who has what equipment and when it was issued⦁ Compliance Automation: Standard-specific requirements automatically monitored and flagged⦁ Mobile Inspections: Complete and document checks from anywhere using your phone or tablet⦁ Inventory Visibility: Real-time status of equipment across all stations and personnel

Vehicle Readiness

Transform daily apparatus checks into actionable data. Track maintenance needs, certification requirements, and testing schedules all in one place, ensuring your fleet is response-ready when seconds count.

⦁ Digital Inspection Forms: Standardized checks with photo documentation capability⦁ Maintenance Workflow: Seamless transition from issue identification to repair⦁ Testing Certification: Track pump tests, ladder certifications, and other requirements⦁ Service History: Complete maintenance records accessible instantly⦁ Defect Tracking: Follow issues from discovery through resolution

Vehicle Readiness

Transform daily apparatus checks into actionable data. Track maintenance needs, certification requirements, and testing schedules all in one place, ensuring your fleet is response-ready when seconds count.

⦁ Digital Inspection Forms: Standardized checks with photo documentation capability⦁ Maintenance Workflow: Seamless transition from issue identification to repair⦁ Testing Certification: Track pump tests, ladder certifications, and other requirements⦁ Service History: Complete maintenance records accessible instantly⦁ Defect Tracking: Follow issues from discovery through resolution

Personnel Development

Streamline probationary evaluations, annual assessments, and qualification tracking. Document career development consistently while eliminating paperwork and preventing lost records.

⦁ Evaluation Consistency: Digitize Probationary, Annual, and Routine Employee Evaluations at Every Level.⦁ Secure and Private: Stored Securely for Future Reviews and Shared on an As Needed Basis.⦁ Compliance Tracking: NFPA and CalOSHA required trainings tracked and logged by firefighters.

Daily Operations

Digitize journal entries, risk assessments, and station status boards. Maintain complete shift documentation while improving situational awareness across your department.

⦁ Digital Journal: Comprehensive shift documentation with media attachment⦁ GAR Assessment: Interactive risk evaluation with visual dashboard⦁ Station Status: Real-time personnel, apparatus, and incident tracking⦁ Weather Integration: Current conditions and forecasts for operational planning⦁ Activity Logging: Complete record of training, public events, and station activities

Daily Operations

Digitize journal entries, risk assessments, and station status boards. Maintain complete shift documentation while improving situational awareness across your department.

⦁ Digital Journal: Comprehensive shift documentation with media attachment⦁ GAR Assessment: Interactive risk evaluation with visual dashboard⦁ Station Status: Real-time personnel, apparatus, and incident tracking⦁ Weather Integration: Current conditions and forecasts for operational planning⦁ Activity Logging: Complete record of training, public events, and station activities

Compliance Assurance

Stop worrying about standards requirements. Fullbox automatically tracks what needs to be done, when it's due, and who needs to do it – across all department operations.

⦁ Multi-Standard Support: Built-in rules for NFPA and department-specific requirements⦁ Deadline Monitoring: Automatic alerts for approaching compliance dates⦁ Documentation Repository: All required files stored and linked to equipment⦁ Audit Preparation: One-click reports for inspection readiness⦁ Regulatory Updates: System adapts as standards evolve

Why We Built Fullbox

It started with a simple mission: help firefighters spend less time on paperwork and more time on what matters.

We built Fullbox alongside active firefighters who live the challenges of department operations every day. Their expertise guides every feature, every screen, and every workflow in our platform.

Our team includes current firefighters who understand firsthand the frustrations of disconnected systems, missing documentation, and time-consuming compliance tracking. They've experienced the reality that information is collected but rarely used effectively.

See FullBox in Action — Book Your Free Demo Today!

Why We Built FullBox

It started with a simple mission: help firefighters spend less time on paperwork and more time on what matters.

We built Fullbox alongside active firefighters who live the challenges of department operations every day. Their expertise guides every feature, every screen, and every workflow in our platform.

Our team includes current firefighters who understand firsthand the frustrations of disconnected systems, missing documentation, and time-consuming compliance tracking. They've experienced the reality that information is collected but rarely used effectively.

See FullBox in Action — Book Your Free Demo Today!

We've witnessed officers spending hours completing forms instead of leading crews. We've seen the frustration of missing equipment records during inspections. We understand the consequences of failed audits due to documentation gaps that could have been prevented.

Most importantly, we recognized that existing software solutions weren't built for the unique needs of the fire service. Generic inventory systems, HR platforms, and fleet management tools all fall short of the integrated approach needed for truly efficient operations.

FullBox changes all that – connecting all operational data into actionable insights that improve readiness, safety, and effectiveness. It's purpose-built for fire departments by people who understand what you face every day.

We've witnessed officers spending hours completing forms instead of leading crews. We've seen the frustration of missing equipment records during inspections. We understand the consequences of failed audits due to documentation gaps that could have been prevented.

Most importantly, we recognized that existing software solutions weren't built for the unique needs of the fire service. Generic inventory systems, HR platforms, and fleet management tools all fall short of the integrated approach needed for truly efficient operations.

FullBox changes all that – connecting all operational data into actionable insights that improve readiness, safety, and effectiveness. It's purpose-built for fire departments by people who understand what you face every day.

The FullBox Difference

Mobile-First

Complete inspections, document incidents, and access critical information from anywhere – with or without connectivity. Fullbox syncs automatically when connection is restored, ensuring no data is lost even in remote locations.Our responsive design works on any device, from desktop computers at headquarters to phones and tablets in the field. The interface adapts to screen size while maintaining functionality, so your team can work efficiently regardless of their location.

Modular Flexibility

Start with what you need most. Add capabilities as you're ready. Fullbox grows with your department.We understand budget constraints and change management challenges. That's why Fullbox is designed for phased implementation – you can begin with a single module and expand as you experience the benefits and build internal support.Each module delivers standalone value while integrating seamlessly with others. Whether you start with equipment tracking and add vehicle management later, or begin with personnel and expand to operations, Fullbox adapts to your priorities.

Standards-Driven

Built around NFPA and industry standards, with automatic updates as requirements change.Fullbox's compliance engine incorporates the specific rules from each applicable standard, from inspection frequencies to documentation requirements. When standards are updated, so is Fullbox – ensuring your department stays current without manual system updates.Our modular approach to compliance means you can track requirements for multiple standards simultaneously, with clear visibility into which standards apply to each piece of equipment and what's needed for full compliance.

Built Through Collaboration

Developed in active partnership with working fire departments to ensure it solves real-world problems.Every feature in Fullbox has been shaped by input from departments like yours. We've observed shift changes, ridden along on apparatus checks, and shadowed equipment managers to understand the daily challenges you face.This collaborative approach means Fullbox fits naturally into your workflows rather than forcing you to adapt to the software. It's built around how firefighters actually work, not how software developers think they should work.

Meeting You Where You Are

We understand that transitioning to a new system can be daunting. That's why Fullbox is designed to seamlessly incorporate your existing data from day one.Our team works directly with your department to import current records, digitize paper documentation, and configure the system to match your operations. Your historical data becomes immediately actionable within Fullbox, preserving institutional knowledge while enhancing its value.We're committed to serving fire departments because you're always serving the community. Your mission is too important to be hindered by inefficient tools and processes.

Meeting You Where You Are

We understand that transitioning to a new system can be daunting. That's why Fullbox is designed to seamlessly incorporate your existing data from day one.Our team works directly with your department to import current records, digitize paper documentation, and configure the system to match your operations. Your historical data becomes immediately actionable within Fullbox, preserving institutional knowledge while enhancing its value.We're committed to serving fire departments because you're always serving the community. Your mission is too important to be hindered by inefficient tools and processes.

Take the Next Step

Every day your department continues with disconnected systems and paper-heavy processes is another day of:

Wasted administrative hours that could be spent on training and community service

Risk of non-compliance penalties that impact your budget and reputation

Incomplete documentation that could affect liability coverage and grant eligibility

Inefficient resource management leading to unnecessary purchases and maintenance costs

Knowledge gaps when experienced personnel retire or transfer

The longer these inefficiencies continue, the more resources they consume – resources your department needs for its core mission of protecting life and property.

See how Fullbox can transform your department operations in a personalized 30-minute demo.

During this no-obligation demonstration, we'll:⦁ Show how Fullbox addresses your specific operational challenges

⦁ Provide a clear implementation roadmap customized to your department

⦁ Explain pricing options that work within public safety budgets

⦁ Answer any questions about security, training, and support

Schedule Your Demo Today

No obligation. No pressure. Just a straightforward look at how Fullbox is helping departments like yours operate more efficiently.

Fullbox Help Center

Welcome to the Fullbox Help Center! Whether you’re a new user or looking to make the most out of the Fullbox platform, this guide will help you navigate our features, enhance efficiency, and ensure compliance for your fire department operations.

Fullbox Video Tutorial

As a Fullbox user, you have access to a comprehensive video tutorial that explains everything from the basics to advanced features of the platform.

Creating Daily Logs

Dashboard & Admin Overview

GAR Assessment Walkthrough

Help & Support Chat

Station & User Management

Troubleshooting & Support

If you encounter any issues or need assistance, our dedicated support team is ready to help with troubleshooting or any questions you may have about using Fullbox.

Contact Us for Help:

Email Support: Send us an email at [email protected]

Phone Support: Call us at (555) 123-4567 during business hours (9 AM - 5 PM, Monday - Friday).

Live Chat: Available through the Fullbox platform by clicking on the Help button in the bottom-right corner of your dashboard.

Submit a Support Ticket: If you need detailed assistance, please submit a support ticket through our website, and our team will get back to you as soon as possible.

FAQs and Additional Resources

FAQs: Visit our Fullbox User FAQ page for more detailed answers to common questions.User Guides: Check out our Fullbox User Guides for step-by-step instructions on using each feature.

Stay Connected

Don’t forget to check for updates on new features, tips, and user guides in our Fullbox Community. By staying connected, you can make the most of all that Fullbox has to offer.Free Demo: Need a refresher? Book a Free Demo and learn how to optimize Fullbox for your department.

Stay Equipped, Stay Safe: The FULLBOX Blog

Explore expert insights, best practices, and the latest updates in PPE management. From optimizing inventory tracking to enhancing firefighter safety, our blog provides valuable resources to help departments streamline operations and protect their teams. Stay informed, stay prepared!

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

New Roles for Fire Department PPC Manager and Technicians

With the new revision of NFPA 1850, Standard on Protective Ensembles for Structural and Proximity Firefighting and Self-Contained Breathing Apparatus (SCBA), the thought of fire departments having a personal....

Jan 1 • 6 min read

Challenges Facing ISPs and the Turnout Gear Cleaning Industry

The care and maintenance of firefighting protective clothing, a critical aspect of firefighter safety, has become a growing focus under NFPA 1850. The role of independent service providers (ISPs) in ensuring the safe and efficient cleaning.....

Jan 1 • 6 min read

Systems Tests for Evaluating the Thermal Protective Perfor....

This supplement describes the state-of-the-art system-level testing methodologies for evaluating the thermal protective performance and heat strain contribution of firefighter protective ensembles. System-level evaluations can be described....

Jan 1 • 13 min read

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

The Real Deal on PPE Care: Everything You Need to Know to Stay Safe and Compliant

Let's cut through the confusion about PPE maintenance. No fluff, just straight talk about what's actually required and why it matters....

Jan 30 • 3 min read

New Roles for Fire Department PPC Manager and Technicians

With the new revision of NFPA 1850, Standard on Protective Ensembles for Structural and Proximity Firefighting and Self....

Jan 1 • 6 min read

Challenges Facing ISPs and the Turnout Gear Cleaning Industry

The care and maintenance of firefighting protective clothing, a critical aspect of firefighter safety, has become a growing focus under NFPA 1850......

Jan 1 • 6 min read

Systems Tests for Evaluating the Thermal Protective Perfor....

This supplement describes the state-of-the-art system-level testing methodologies for evaluating the thermal protective performance....

Jan 1 • 13 min read

Feb 13 • 3 min read

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can feel like trying to navigate a smoke-filled structure without a TIC. Let's break this down into something that actually makes sense on the apparatus floor.

The Bottom Line Up Front

Your department has to:

• Make sure your gear isn't older than 10 years

• Get you properly fitted PPE that • meets NFPA standards

• Have you inspect your gear before and after each use

• Get your gear professionally inspected every year

• Train you on how to use, clean, and maintain your gear

• Keep records of everythingYou have to:

• Actually inspect your gear (yeah, every time)

• Report problems when you find them

• Keep your gear clean

• Know how to use it properly

• Not use expired or damaged gear

Let's Talk Real Money

Here's why your chief loses sleep over this stuff. If CalOSHA shows up and finds problems, the fines are no joke:• Basic paperwork violations: $16,285 each

• Serious safety violations: $25,000 each

• If they find the same problem again: Up to $162,851

• If someone gets hurt because of violations: $140,000And get this - they can charge these fines PER FIREFIGHTER affected. Fifty folks with expired turnouts? You do the math.

The Gear Lifecycle: What You Need to Know

When You Get New Gear

• It needs to fit YOU, not just any firefighter

• You should get trained on how to use it

• The department needs to document everything about itThink about it like apparatus maintenance. You wouldn't skip truck checks, right? Same goes for your PPE.Daily Use

Before you hop on that rig, your gear needs a quick check:• Obvious damage?

• All parts there?

• Clean enough to be safe?Found something wrong? Report it. Your department HAS TO fix it or replace it. That's not just policy - it's law.Annual Inspections

Just like your SCBA gets tested annually, your PPE needs a professional once-over every year. This isn't optional. Someone who knows what they're looking at needs to inspect every piece.The 10-Year Rule

Your turnouts have an expiration date - 10 years from when they were made, not when you got them. After that, they're done. No exceptions, no extensions.

Wildland Specific Stuff

If you're on the wildland side:• Your fire shelter better be right there with you

• Your helmet needs to meet NFPA 1977

• Your eye pro needs to work with your helmet

What This Means on the Ground

For You

• Know your gear

• Check it regularly

• Report problems

• Keep it clean

• Know when it expiresFor Your Officers

• Keep the records

• Schedule the inspections

• Replace gear on time

• Make sure everyone's trained

• Keep spare gear ready

The Real Talk About Compliance

Look, nobody loves paperwork. But here's the deal - these requirements exist because firefighters got hurt or killed. Every single rule is written in someone's blood or sweat.Your department has two choices:1. Stay on top of this stuff and keep everyone safe

2. Risk massive fines AND put firefighters at risk

What You Can Do

1. Know Your Gear

• When did you get it?

• When was it made?

• When was its last inspection?2. Speak Up

• See something wrong? Say something

• Don't know how something works? Ask

• Need new gear? Request it3. Keep Records

• Take photos of damage

• Document when you report issues

• Keep track of your training

Bottom Line

This isn't just about avoiding fines. It's about making sure everyone goes home after every call. Your gear is your last line of defense. Treat it that way.Remember:

• The department has to provide safe gear

• You have to use it properly

• Everyone has to document everything

• When in doubt, report itStay safe out there, and take care of your gear so it can take care of you.

Quick Reference: Red Flags for Your PPE

🚩 Time to Report It If:• Rips, tears, or holes

• Broken closures

• Missing reflective strips

• Discoloration

• Worn areas

• Contamination

• Equipment more than 9 years old

• Anything that makes you question its safetyThe cost of reporting is zero. The cost of not reporting could be everything.

Remember: This post covers the basics but isn't a replacement for your department's specific policies or the full CalOSHA regulations. When in doubt, check your SOPs or ask your safety officer.

Recent Posts

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

The Real Deal on PPE Care: Everything You Need to Know to Stay Safe and Compliant

Let's cut through the confusion about PPE maintenance. No fluff, just straight talk about what's actually required and why it matters....

Jan 30 • 3 min read

Jan 31 • 2 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what Independent Service Providers (ISPs) do with your life-saving equipment.

Advanced Inspection: More Than Just Looking for Holes

When your gear arrives at a verified ISP, it goes through a seriously thorough inspection process. We're talking way beyond what's possible at the station.Layer by Layer Breakdown

1. Outer Shell:

• UV light inspection for hidden damage

• Detailed seam inspection using magnification

• Light degradation testing

• Reflective trim testing for retroreflectivity

• Hardware testing (closure systems, clips, hooks)2. Moisture Barrier:

• Water penetration testing

• Cup test for leaks

• Hydrostatic testing

• Seam seal verification

• Chemical degradation checks3. Thermal Liner:

• Thermal protection testing

• Layer separation inspection

• Material degradation checks

• Batting compression testing

• Seam integrity verification

Advanced Cleaning: Better Than Your Station's Washer

Here's what happens during that deep clean:

Pre-Cleaning Assessment

• Initial photos for documentation

• pH testing of soiled areas

• Assessment of contamination types

• Identification of special cleaning needs

• Documentation of existing damage

The Cleaning Process1. Pre-treatment:

• Specialized spot cleaning for heavy contamination

• Treatment of specific problem areas

• Application of appropriate cleaning agents2. Advanced Washing

• Commercial-grade specialized washing machines

• Verified water temperatures

• Proper load size for maximum cleaning

• Specialized detergents designed for PPE

• Multiple wash cycles as needed3. Specialized Drying:

• Temperature-controlled drying

• Air drying when specified

• Humidity-controlled environment

• No UV exposure during dryingPost-Cleaning

• Water repellency testing

• pH testing to ensure neutrality

• Inspection of cleaned areas

• Documentation of cleaning results

• Final inspection before return

Why It Matters

When you get your gear back, you might think "it just looks cleaner." But here's what really happened:• Carcinogens removed from deep within the fibers

• Thermal protection capabilities verified

• Water protection confirmed

• Structural integrity ensured

• Full documentation for your records

The Bottom Line

Advanced inspection and cleaning isn't just about checking a box for compliance. It's about making sure every layer of your gear is ready to protect you when you need it most. The detailed processes, specialized equipment, and trained technicians all work together to ensure your PPE can do its job - keeping you safe.

What to Expect

• Remove personal items before sending

• Document any known issues

• Keep copies of testing results

• Check paperwork upon return

• Review findings with your PPE manager

Pro Tips

• Remove personal items before sending

• Document any known issues

• Keep copies of testing results

• Check paperwork upon return

• Review findings with your PPE manager

Remember: These processes aren't just about meeting requirements - they're about making sure you go home at the end of your shift.

Recent Posts

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

The Real Deal on PPE Care: Everything You Need to Know to Stay Safe and Compliant

Let's cut through the confusion about PPE maintenance. No fluff, just straight talk about what's actually required and why it matters....

Jan 30 • 3 min read

Jan 30 • 3 min read

The Real Deal on PPE Care: Everything You Need to Know to Stay Safe and Compliant

Let's cut through the confusion about PPE maintenance. No fluff, just straight talk about what's actually required and why it matters. Whether you're a probie or a 20 year vet, this guide will help keep you safe and compliant.

The Daily Check: Your Life Depends On It

Every shift starts the same way - and yes, PPE inspection is mandatory per CalOSHA 3410(c). This isn't optional, and here's why: your gear is literally the last line of defense between you and disaster.

What you MUST check daily:

• Rips, tears, holes (obvious stuff)

• Damaged closure systems

• Seam integrity

• Reflective strip condition

• Thermal liner issues

• Moisture barrier problems

• Shell material conditionPro Tip: Make it part of your morning routine. Coffee, gear check, truck check. Five minutes could save your life.

Cleaning Your Gear: Let's Get Real About Cancer Prevention

Advanced cleaning isn't just recommended - it's REQUIRED by law (CalOSHA 3410(d)). Those invisible carcinogens don't care about your years of service or how tough you are.

1. After-Fire Basics:

• Initial rinse at scene when possible

• Full cleaning following manufacturer's specs

• Using manufacturer-approved cleaning agents only

• Proper drying procedures

• Documentation of cleaning2. Advanced Cleaning (Mandatory):

• Machine washing as often as necessary to remove soiling

• Using appropriate cleaning agents (not just any detergent)

• Following manufacturer's cleaning procedures exactly

• Proper documentation of each cleaningRemember: "It's not that dirty" isn't a valid excuse. If it's been exposed, it needs to be cleaned. Period.

Training Requirements: Knowledge is Survival

CalOSHA 3410(e) isn't messing around. You MUST be trained on:

• How your gear should fit

• Limitations of your PPE

• Proper donning and doffing

• Inspection procedures

• Cleaning protocols

• Storage requirementsAnd yes, this training must be documented and kept for 3 years. It's not just paperwork - it's proof you know how to use the equipment that keeps you alive.

When to Say Goodbye: Gear Retirement

The law is clear on this one: 10 years from manufacture date, it's done (CalOSHA 3410(f)). But sometimes gear needs to retire early:• Thermal damage (even sunlight)

• Physical damage beyond repair

• Failed inspection points

• Contamination that can't be cleaned

• Heat stress indicator activation

Quick Reference: What's Required (Not Optional!)

Making It Work: Building Good Habits

CalOSHA 3410(e) CalOSHA 3410(f) CalOSHA 3410(c) Look, we know it seems like a lot. But just like everything else in the fire service, it becomes second nature with practice. Here's how to make it happen:1. Set daily reminders for gear checks

2. Keep inspection forms easily accessible

3. Document issues with photos

4. Make it a crew activity

5. Use downtime wisely for more thorough checks

6. Schedule regular advanced cleaning

7. Keep a cleaning log near your washing equipment

The Bottom Line

Every one of these requirements exists because someone paid the price to learn why they're necessary. Your gear is your lifeline - treat it that way. These aren't just regulations; they're your insurance policy for going home to your family after every shift.

Need Help?

Don't hesitate to:• Ask your company officer

• Talk to your PPE manager

• Review department SOPs

• Raise questions during training

• Document concerns about gear condition

• Reach out to Sukh at [email protected] to figure out how technology can help reduce this headache and make it easy to keep gear both clean and compliant.

Remember This

You signed up to be a firefighter because you want to help others. Part of that job is taking care of yourself and your equipment. Every inspection, every cleaning, every documentation - it all adds up to one thing: making sure you're ready when the tones drop and someone needs you

Recent Posts

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

Jan 1 • 6 min read

New Roles for Fire Department PPC Manager and Technicians

Photo: City of Santa Rosa (CA) Fire Department

By Robert Tutterow, President, F.I.E.R.O., and Bruce Varner, Chief (Ret.), Santa Rosa (CA) Fire Department

With the new revision of NFPA 1850, Standard on Protective Ensembles for Structural and Proximity Firefighting and Self-Contained Breathing Apparatus (SCBA), the thought of fire departments having a personal protective clothing (PPC) manager and technicians has formally arrived. If you have heard of this, the term PPE was used rather than PPC. The NFPA opted to change the terminology and acronym as there are already SCBA technicians, and SCBA is considered PPE. For the 1850 document, personal protective clothing refers to helmets, hoods, gloves, boots, coats, and pants.

Why are these roles needed? It is only in the past few years that PPC has been getting the focus it needs. The emerging knowledge about contaminants and the subsequent cancer rates bring a logical spotlight on PPC. The time is now for designated fire department PPC. Think about it—we already have Firefighter I, Firefighter II, driver/operator, EMT, paramedic, investigator, inspector, and other qualification requirements. We have certifications for emergency vehicle technician, health and safety officer, incident scene safety officer, traffic incident management person, and other tasks designed around an NFPA standard and tested through the Pro Board.

As the world of contamination and PPC evolves, the more we know, the more we realize we need to know. The PFAS issue is an ideal example. New information about PPC is coming at an accelerating rate. It is imperative that fire departments have personnel who get “up to speed” and remain “up to speed” about the PPE world. We now know our PPC is a health hazard if not properly maintained. After all, we are talking about protecting every department’s most valuable asset.

Only a few fire departments have robust PPC programs that include selection, cleaning, repair, storage, and retirement. There is no doubt these departments have one or more people who have passionately engaged in learning as much as they can about PPC—”the last line of defense in protecting firefighters from hazards that cannot be controlled any other way.” But what about the other fire departments? Their commitment to a “real” PPC program varies greatly. Unfortunately, far too many departments have no semblance of a PPC program, as evidenced by many of the photos we all see in national publications and other media sites.

What are the roles of a PPC manager and PPC technicians?

PPC MANAGER

The new official NFPA definition of a PPC manager is “an individual assigned or authorized to manage the organization’s PPC program.” The functions of the PPC manager include, but are not limited to, the following:

Maintains an understanding of current NFPA standards (NFPA 1970) as well as other required standards and laws (e.g., OSHA) for the purchase of appropriate PPC.

Conducts a review of the department operations to complete a risk assessment for the type of PPC required.

Establishes a policy and procedures for the proper use and care of PPC within the organization that must be reevaluated periodically (at least annually).

Establishes a system to monitor, track, and document PPC over its life.

Determines the useful life of the PPC.

Establishes criteria for assessing PPC selection.

Actively participates in the selection of the department’s PPC.

Establishes processes for returning product that does not meet specifications.

Follows retirement and disposal criteria of PPC.

Establishes procedures for the inspection, cleaning, and repair of PPC.

Establishes a process for the fitting of gear for firefighters.

Develops a training program specific for the job functions of the PPC technicians.

Develops a training program for the entire department detailing the proper fit, function, limitations, and handling of PPC, as well as the expected inspection and routine cleaning of PPC. Ensures training is delivered to all members who use PPC.

Assists with, including providing input to, the budgeting process and strategic planning related to PPC acquisition and maintenance.

Establishes exposure procedures and controls for the handling of contaminated PPE sent for cleaning, inspection, and/or repair.

PPC TECHNICIANS

The official NFPA definition of a PPC technician is “an individual assigned or authorized to ensure the organization’s PPE is in proper working condition and is compliant with relevant standards.” The PPC technician role may be performed by the PPC manager, another employee of the organization, a verified organization, or a verified ISP or a combination thereof, depending on the organization’s structure or size. The functions of the PPC technician include, but are not limited to, the following:

Examines and files information that comes with PPE.

With the PPC manager, establishes the schedule for cleaning, inspecting, and repairing PPC.

Determines the need for repair or additional cleaning (bio or specialty).

Coordinates all repairs.

Is trained in advanced inspection procedures.

Determines ability to repair.

Documents the action taken on the PPE in the tracking system.

Consults the element manufacturer on major repairs.

Consults the element manufacturer regarding visibility marking repair.

Evaluates the moisture barrier repair requirement.

Consults with the manufacturer for major A seam restitching.

Consults with the manufacturer for major B seams.

Performs zipper repair complexity.

Performs hook-and-loop repair complexity.

Evaluates helmet serviceability.

Determines footwear repair feasibility.

Reports PPC health and safety concerns to the PPC manager.

Note: Depending on the level of training and the organization’s resources, the PPC technicians may complete some or all repairs or coordinate sending PPC needing repair out to an appropriate ISP for the necessary repairs. Any items sent out for repair would be inspected by the PPC technician prior to being returned to service.Some fire departments might say there is no need for a PPE technician because their personnel are trained by a PPE manufacturer when they purchase PPE from them. But let us be honest, what kind of training is that? Is there testing on the curriculum? If so, does anyone ever fail? We would suggest that such training, while of some value, is basically a “participation trophy.”If the fire service is going to take contamination control with the subsequent related cancers as seriously as we should, then developing PPC manager and technician qualifications is a must. As a service, PPC manufacturers are held to very strict standards and their products must be certified to those standards by a third-party agency such as UL or SEI. It is only reasonable that the fire service holds itself accountable for the proper care of our PPC.

Original Source: This article is from Fire Engineering. For the full article, visit New Roles for Fire Department PPC Manager and Technicians on Fire Engineering’s website.

Original Source: This article is from Fire Engineering. For the full article, visit New Roles for Fire Department PPC Manager and Technicians on Fire Engineering’s website.

Recent Posts

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

Jan 1 • 6 min read

Challenges Facing ISPs and the Turnout Gear Cleaning Industry

BY TIM TOMLINSON, ENGINEER/PARAMEDIC, ADDISON (TX) FIRE DEPARTMENT; CHAIR, NFPA TECHNICAL COMMITTEE ON STRUCTURAL AND PROXIMITY FIRE FIGHTING PROTECTIVE CLOTHING AND EQUIPMENT

The care and maintenance of firefighting protective clothing, a critical aspect of firefighter safety, has become a growing focus under NFPA 1850. The role of independent service providers (ISPs) in ensuring the safe and efficient cleaning of turnout gear is more crucial than ever. However, ISPs face numerous challenges in keeping up with increasing demand, evolving regulations, and advancements in cleaning technologies. These obstacles not only impact the industry itself but also pose broader implications for firefighter safety and the sustainability of turnout gear.

Frequently Asked Questions on Restricted Substances in Protective Clothing

How Do I Comply with NFPA 1851? Five Options

New Roles for Fire Department PPC Manager and Technicians

Figure D. Balancing Technology and Resources for Improved Cleaning

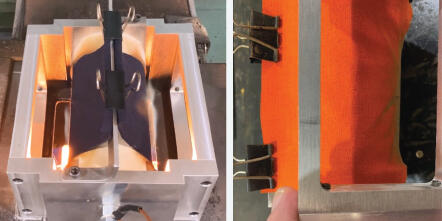

Some fire departments are increasingly having to find space and resources to provide advanced cleaning of their PPE. (Figure D courtesy of author.)

INCREASING AWARENESS OF CONTAMINATION RISKS

Over the past decade, awareness of the risks associated with contaminated firefighter gear has surged. Studies have revealed the long-term health hazards posed by carcinogens and toxic particulates embedded in firefighting textiles. This growing understanding has fueled the demand for improved cleaning processes and faster turnaround times. ISPs must now rise to meet these expectations while ensuring that their cleaning methods are both thorough and compliant with updated standards.However, many of the current commercial laundry technologies, while effective, have notable limitations. Deeply embedded contaminants in multilayered textiles can often evade even the most rigorous cleaning processes. This gap in cleaning efficiency has sparked interest in emerging technologies such as ultrasonic cleaning, advanced ozone systems, improvements in wet washer extractor processes, and liquid CO2 solutions, as well as others. While these innovations show promise, continued improvements and more sophisticated technologies come at a significant cost—both for ISPs investing in the equipment and for fire departments potentially absorbing higher cleaning fees.

THE COST OF EMERGING TECHNOLOGIES

The introduction of cutting-edge cleaning technologies poses a double-edged sword for ISPs. On the one hand, they offer the potential for higher efficiency and better removal of harmful contaminants. On the other hand, the high upfront investment and operational costs associated with some of these technologies raise critical questions: Can ISPs afford to make these capital investments? Will fire departments be willing to pay a premium for enhanced cleaning services?The financial burden is further compounded by ongoing work on regulations that could require ISPs and fire departments to adopt additional precautions depending on your state or authority having jurisdiction, such as effluent filtration systems to prevent secondary contamination. These systems, while necessary to protect the environment and personnel, add another layer of complexity and cost. As regulations continue to evolve, ISPs must constantly adapt to remain compliant in meeting the demands of the regulations and the fire service, often with limited resources.

BALANCING EXPECTATIONS AND REALITY

Another challenge lies in aligning the fire service’s expectations with the practical capabilities of cleaning technologies. Firefighters understandably demand the highest level of safety, but is it realistic to expect that all contaminants can be removed from turnout gear? While advancements in textiles and coatings have continued, this could impact the durability and cleanability of firefighting gear. This will require the fire service to evaluate more than ever the trade-offs between expected performance requirements on purchasing gear and the impact of care and maintenance over the life of that gear and realistic contamination removal efficiencies. The industry must work toward setting realistic benchmarks that balance contamination removal with the inherent limitations of cleaning methods.Moreover, increased cleaning frequency raises concerns about the long-term durability of turnout gear. Each cleaning cycle, no matter how advanced the technology, contributes to wear and tear. The introduction of new textiles, coatings, and treatments will impact this further. Although great improvements are being made, the performance over extended periods remains to be seen. ISPs and fire departments must work collaboratively to find a middle ground that ensures safety without compromising the longevity of the gear.

IMPROVING VALIDATION OF CLEANING EFFICIENCY CLAIMS

As ISPs and manufacturers introduce new cleaning products and processes, there is an urgent need to validate their claims of cleaning efficiency. Firefighter safety depends on more testing and validation to ensure that cleaning technologies perform as advertised. Too often, products are brought to market with vague or overstated claims, leaving fire departments uncertain about their true effectiveness.Standardized validation protocols are proposed to be developed to objectively measure how well cleaning products and processes remove harmful contaminants. Independent testing organizations and regulatory bodies must play a central role in establishing these protocols. Validation metrics should include not only contaminant removal but also the impact of cleaning on the durability and protective qualities of firefighting gear.Without reliable validation, fire departments and ISPs risk investing in technologies that fail to meet their safety expectations. By prioritizing transparency and accountability, the industry can build trust and ensure that every cleaning solution is backed by trusted evidence. This step is crucial for protecting firefighters from unnecessary exposure to contaminants while also safeguarding the significant financial investments made in turnout gear.

LOOKING AHEAD

The turnout gear cleaning industry stands at a crossroads. ISPs face mounting pressure to adopt advanced cleaning technologies, meet stricter regulatory requirements, and satisfy the fire service’s ever-increasing demands—all while maintaining profitability. As the industry evolves, collaboration between ISPs, regulatory bodies, and fire departments will be critical. Open communication and realistic goal setting will ensure that advancements in cleaning processes benefit all stakeholders without creating unsustainable financial burdens.Ultimately, the challenges faced by ISPs underscore a broader commitment to firefighter safety. By addressing these issues head-on, the industry can pave the way for a safer, cleaner, and more sustainable future for the men and women who risk their lives to protect others.

Original Source: This article is from Fire Engineering. For the full article, visit Challenges Facing ISPs and the Turnout Gear Cleaning Industry on Fire Engineering’s website.

Recent Posts

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

Jan 1 • 13 min read

Systems Tests for Evaluating the Thermal Protective Performance and Heat Strain Contribution of Protective Elements and Ensembles in Structural Firefighter Gear

BY ROGER BARKER, SHAWN DEATON, JOHN MORTON-ASLANIS, AND MARC MATHEWS, NORTH CAROLINA STATE UNIVERSITY (NCSU) TEXTILE PROTECTION AND COMFORT CENTER (TPACC)

This supplement describes the state-of-the-art system-level testing methodologies for evaluating the thermal protective performance and heat strain contribution of firefighter protective ensembles. System-level evaluations can be described as using either the skin-outward approach (where material composites are testing in the sample configurations that they are worn in, including all layers) or the full-garment or ensemble approach (where the entire garment or ensemble is evaluated “as-worn” with all other ensemble elements).This sidebar discusses the following test methods in Annex G of the newly revised and consolidated NFPA 1970:

• Full Ensemble and Element Thermal Testing

◦ Full Ensemble Flash Fire

◦ Cylinder Thermal Protective Performance Test (C-TPP)

• Full Ensemble and Element Physiological Testing

◦ Measured Ensemble Heat Loss Test

◦ Measured Ensemble Evaporative Resistance Test

◦ Glove Evaporative Resistance Test

◦ Footwear Evaporative Resistance Test

◦ Hood Evaporative Resistance Test

FULL ENSEMBLE FLASH FIRE TESTING

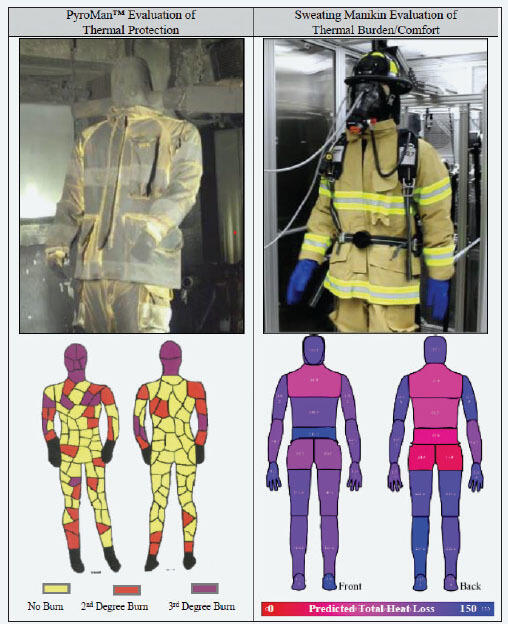

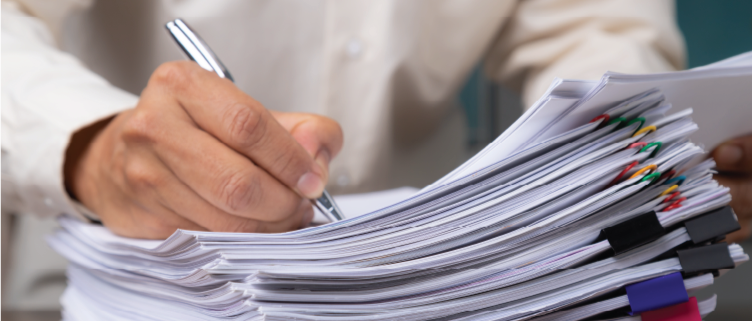

This testing is based on ASTM F1930-23, Standard Test Method for Evaluation of Flame-Resistant Clothing for Protection Against Fire Simulations Using an Instrumented Manikin. The test allows the measurement of the thermal protection provided by different materials, garments, clothing ensembles, and systems when exposed to a fire. In the test, a stationary upright instrumented manikin is exposed to a simulated fire environment having a controlled heat flux, flame distribution, and duration (Figure B1). The average exposure heat flux is 84 kW/m2, which can last as long as 20 seconds.Energy transferred through and from the test specimen during and after the exposure is measured by sensors that are distributed as uniformly as possible within each area on the manikin, located at the surface of the manikin. These are used to predict second- and third-degree burn injuries resulting from the exposure. For full garment evaluations, F1930 reports if there were predicted second- and third-degree burn injuries and their respective locations on the manikin (Figure B2). Subjective observations can include after flame or ignition of the garment the amount of smoke generated; if the garment had shrinkage; char formation; and if it melted, broke open, or fell apart.

Figure B1. (L-R) Thermal Instrumented Manikin, Clothed Manikin, and Flame Engulfment of Clothed Manikin

Figures courtesy of authors.

Figure B2. ASTM F1930 Output Showing No Burn (Yellow), Predicted Second-Degree Burn (Orange), and Predicted Third-Degree Burn (Purple)

One of the drawbacks of F1930 is that the effects of movement on thermal protection are not addressed. A firefighter may also have a significant reduction in fire protection under dynamic conditions when compared to the standard static testing conditions performed in ASTM F1930.

SEPARATE ELEMENT THERMAL TESTING

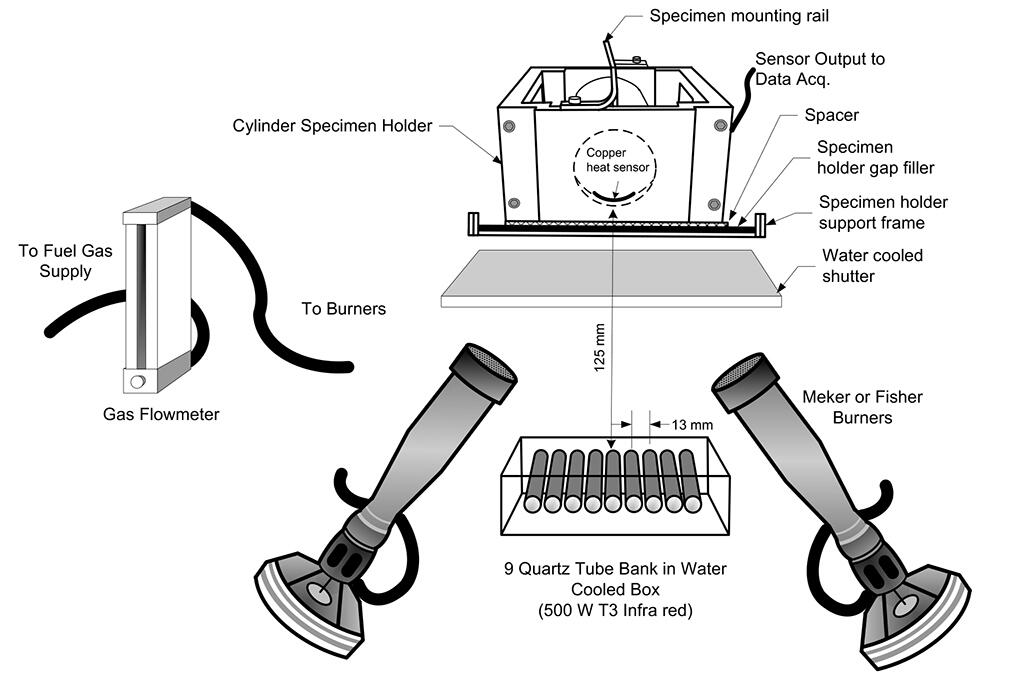

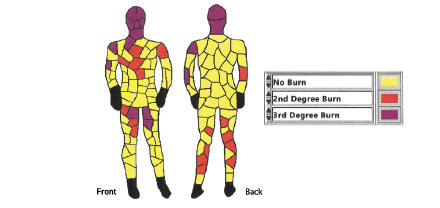

Heat transmission through clothing is largely determined by its thickness, including any air gaps. The air gaps can vary considerably in different areas of the human body. This method provides a means of grading materials when tested under standard test conditions where an air gap exists between the fabric and the sensor. During the exposure, fabric temperatures can exceed 400°C. At these temperatures, some fabrics are not dimensionally stable and can shrink or stretch. The cylindrical geometry used in this test method allows such motion to occur, which will affect the time to achieve the end point of the test.This equipment for the test method is like ASTM F2700 (used for TPP testing) in that it uses the same energy heat source, water-cooled shutter, and data acquisition. It measures the heat transfer through protective clothing materials using a copper calorimeter (Figure B3). This test method differs from Test Method F2700 in the usage of an instrumented cylinder mounted horizontally, which allows for the thermal shrinkage of materials when tested. A test specimen is wrapped around an instrumented test cylinder that is horizontally positioned and exposed to a combined convective and radiant heat source with an exposure heat flux of 84 ± 2 kW/m2 (Figure B4). Using the X-inch spaced configuration allows samples to shrink, eliminating the air gap and increasing the rate of heat transfer as shown in Figure B5.

Figure B3. Cylindrical TPP Sample Holder Without and with Sample Material

Figure B4. Cylindrical TPP Test Configuration with Sample Holder, Burners, and Radiant Heat Source

Figure B5. Exposure of Material in Cylindrical TPP Test Apparatus with Sample Shrinkage

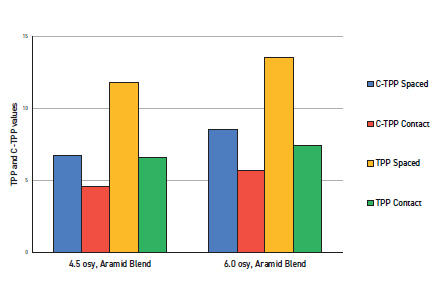

The data in Figure B6 shows testing a material that is not dimensionally stable at higher temperatures. The TPP test shows a 78% increase in protection when going from contact to spaced configuration while the C-TPP only shows a 45% increase in protection.

Figure B6. Comparison of C-TPP and Standard TPP Results for Two Materials in Different Test Configurations of Spacing

SYSTEMS TESTS FOR EVALUATING CONTRIBUTION TO FIREFIGHTER HEAT STRESS

Sweating manikins. Guarded sweating hot plates measure heat loss only through flat swatches of clothing materials. Sweating manikins are used to measure the heat loss and breathability of full-scale PPE clothing systems. The sweating manikin (Figure B7) measures insulation, evaporative resistance, and heat loss using the same principles as the sweating guarded hot plate that is used for both THL and Ret. The difference is that the sweating manikin has a human form that accounts for the air layer between garments and the human body, reinforcements, garment design, and fit. The manikin form consists of 22 separately heated zones. Moisture brought to the manikin’s surface causes it to “sweat,” enabling measurement of a garment’s ability to dissipate evaporative heat. The Newton type manikin at NCSU is 175 cm in height, with a skin surface area of 1.8 m2, to simulate an adult male. It has 134 sweating holes evenly distributed over the manikin surface.

Figure B7. Newton (Male) and Liz (Female) Sweating Manikins at NCSU TPACC

Sweating manikins are used to measure garment insulation and evaporative resistance according to ASTM FI291, Standard Test Method for Measuring the Thermal Insulation of Clothing Using a Heated Manikin, and ASTM F2370, Standard Test Method for Measuring the Evaporative Resistance of Clothing Using a Sweating Manikin. Both dynamic and static tests can be conducted of clothing breathability. Dynamic tests involve using an external mechanical drive to “walk the manikin” to create forced convection through body motion. Dynamic manikin tests typically produce larger heat loss through both evaporative heat transfer and dry heat transfer than static manikin tests.Evaluating heat loss through firefighting elements (gloves, boots, and hoods). Sweating thermal body form instrumentations (hand, foot, and head) is designed to evaluate heat and moisture management properties of glove, boot, and hood systems (Figure B8). These instruments simulate heat and sweat production, making it possible to assess the influence of ensemble elements on the thermal comfort properties for a given environment. Simultaneous heat and moisture transport through the various element systems and variations in these properties over different areas of the body form can be quantified.

Figure B9. Heat Loss Measured on Protective Elements (Hand, Foot, and Head)

The hand, foot, and head manikins operate on the same principles as the sweating manikin system. They consist of several features designed to work together to evaluate comfort and/or heatstress. Housed in a climate-controlled chamber, each body form is divided into separate sections or zones, each of which has its own sweating, heating, and temperature measuring system. Using a pump, preheated water is supplied from a reservoir located outside of the environmental chamber. An internal sweat control system distributes moisture to “sweat glands” across the surface of the manikin. Water supplied to the simulated sweat glands is controlled by operator entry of the desired sweat rate. Each sweat zone is individually calibrated, and the calibration values are used by the control software to maintain the sweat rate of each section.Continuous temperature control for the hand segments is accomplished by a process control unit that uses analog signal inputs from separate resistance temperature detectors (RTDs). These evenly distributed RTDs are used instead of point sensors because they provide temperature measurements in a manner such that all areas are equally weighted. Distributed over an entire section, each RTD is embedded just below the surface and provides an average temperature for each section. Software establishes any discrepancy between temperature set point and the input signal and adjusts power to section heaters as needed.Insulation and breathability of each ensemble element are measured following procedures for sweating thermal manikin testing adapted for testing of gloves on a hand manikin (ASTM F3426, Standard Method for Measuring the Thermal Insulation of Clothing Items Using a Heated Manikin Body Forms and ASTM F 3672, Standard Method for Measuring the Evaporative Resistance of Clothing Items Using a Heated Manikin Body Forms, respectively).Heat Loss Potential (W/m2) is calculated for a standard environment by combining both the dry and sweating components of heat loss measured in their respective states.

Figure B8. Manikin Forms for Testing Gloves, Boots, and Hoods at NCSU TPACC

Note: Redder, light colors represent lower heat loss.

HUMAN EVALUATED WEAR TESTING OF FIREFIGHTER ENSEMBLES

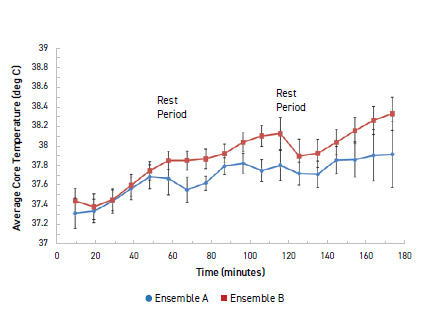

Full ensemble wear testing is the ultimate assessment for indicating user opinion and acceptance of a garment ensemble. A specific and limited human subject pool, following a protocol based on ASTM F2668, Standard Practice for Determining the Physiological Responses of the Wearer to Protective Clothing Ensembles, is used to evaluate protective garments where heat stress might impact wearer performance of job tasks.Participants are instrumented to collect physiological data on heart rate, skin temperature, and core temperature while following a prescribed protocol, often on a treadmill at a controlled rate ofexercise (Figure B10). Wireless sensor technologies are used for data transmission and collection of readings on bodily stress indicators.This advanced physiological monitoring platform is cutting edge technology that combines human physiology measurements with human movement. Wearer vital signs are transmitted noise-free via a Bluetooth interface. Data can be transmitted continuously or in intervals and can be viewed in real time. These data can then be plotted to show ensemble differences (Figure B11).

Figure B10. Human Subject Testing on a Treadmill with Physiological Monitoring

Figure B11. Sample Data Showing Core Temperature Differences Between Two Ensembles Over Selected Exercise Regime

TRADEOFFS BETWEEN PROTECTION AND WEAR COMFORT IN FIREFIGHTER GEAR

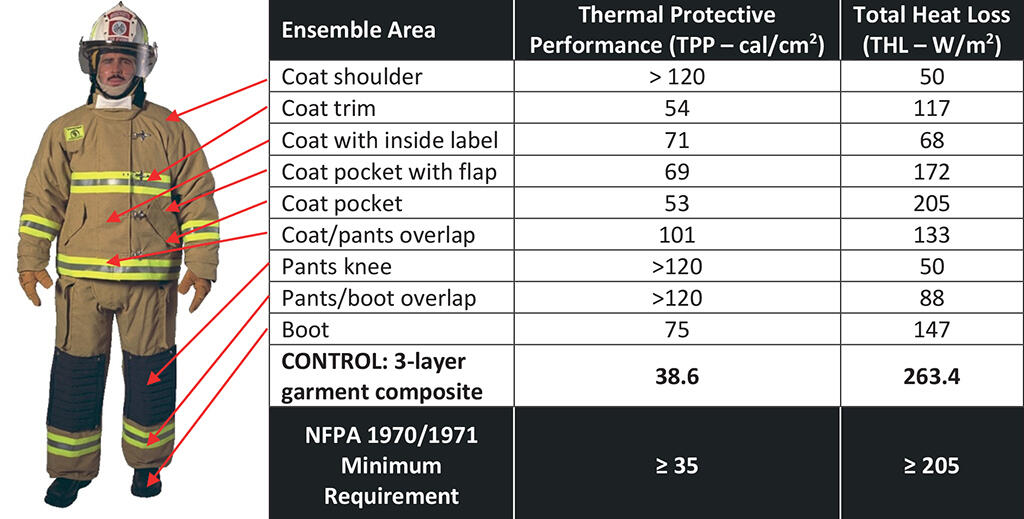

Traditionally, protective ensembles for firefighters were designed to primarily address the delicate balance between thermal protection and thermal comfort, with protection from emergency fireground conditions such as flashover being of highest importance due to the nature of responding to structural fires. Over the past few decades, the number of line-of-duty deaths associated with thermal injury on the fire scene decreased, while the fatalities associated with heat strain and cardiac events remained. This trend began to indicate to the fire service community and manufacturers that the protection-to-comfort balance was favoring thermal protection at the expense of the firefighter’s physiological health and well-being. With this realization, the NFPA committees began to revise the product standards across the first responder applications to place higher importance on heat loss requirements for all ensembles. For several years, these two parameters—thermal protective performance (TPP) and total heat loss (THL)—continued to be the main two concerns for the development of firefighter garment and ensemble designs. However, just a few years ago, this balancing act became more complicated with the newfound awareness of firefighter exposure to toxic fireground contaminants and the epidemic of cancer in the fire service. Now research studies are investigating exposure to both smoke particles as well as fireground vapors, manufacturers are developing smoke-resistant turnout garments and protective hoods, and the NFPA committees are once again attempting to revise the standards to address this newly realized threat to firefighter safety.Historically, this delicate balance between the protective capacity of a specific type of gear and the physiological burden that it adds to the first responder has been assumed to be achieved mostly by material-level performance evaluations and requirements specified by the NFPA product standards. The issue with this assumption is that material-level testing alone cannot predict the complex interactions that occur when these material composites are made into garments and donned with multiple other pieces of equipment.For instance, the thermal protective performance of the turnout composite (outer shell, moisture barrier, and thermal liner) must exceed a value of 35 (which relates to 17.5 seconds before a second-degree burn is predicted). This evaluation does not consider any areas of overlap in the ensemble such as with pockets, the jacket overlapping the pants, or the fact that all firefighters wear some sort of base layer beneath the turnout garment, which further increases the protective performance of the system.On the other hand, the base composite also must meet or exceed a total heat loss value of 205 W/m2, but additional insulating layers can then be added during garment manufacturing to improve thermal protection without ever evaluating the effect on the heat loss of the final product.Figure B12 illustrates the variability in TPP and THL values across a typical turnout ensemble as measured at NCSU TPACC in a recent AFG-funded research project.

Figure B12. Variability of TTP and THL Values Across a Turnout System

These combined effects are not measured using current material-level tests. While the base turnout composite that is shown exceeds the minimum TPP and THL requirements, the inverse relationship between these two values can clearly be seen; when TPP increases, THL in that area decreases significantly.Because the modern structural firefighting (also used in WUI environments) ensemble is comprised of a turnout jacket and pants with multiple fabric layers, reflective trim, pockets, and padding, in addition to a base ensemble (station uniform), protective hood, gloves, boots, a helmet, and SCBA, the only approach to assess the true performance as a firefighter would experience it is with a system-level evaluation. These types of evaluations that consider the firefighter as a whole system instead of individual, unconnected components provide the capability to investigate the interoperability of different ensemble components, the effects of garment fit and designs, and the integrity of interfaces between ensemble elements. An evaluation of the same turnout composite and ensemble using PyroMan™ and a thermal sweating manikin (Figure B13) provides an example of the utility of evaluating the ensemble at the system level. The detailed data that can be collected across the manikin body provides many more insights into the actual performance of the whole ensemble than a simple material-level TPP or THL evaluation can provide.

Figure B13. Graphical Diagrams Produced by Pyroman and Sweating Manikin Tests

The realism of fire manikin evaluation of responders’ ensembles by adding dynamic movement to the manikin during the fire exposure has enabled evaluation of the effects that create mechanical stress on the gear, revealing weakness in thermal protection not always apparent in static testing. Heat from flames produces significant thermal degradation to the materials directly exposed to flame contact. Some types of char-forming outer shell materials are badly degraded in flame exposures, yet the turnout suit continues to provide protective insulation in static conditions. In actual fire exposures, mechanical stresses produced by firefighters’ natural body movements in escaping the flames may cause degraded clothing layers to break open, leading to catastrophic breakdown of the ensemble’s thermal protective envelop.Therefore, data on ensemble TPP provide opportunity to evaluate the value of material-level flame and thermal shrinkage tests. These advances will present opportunities to harmonize TPP and heat-resistant requirements for materials used in ensemble elements.Authors’ note: Portions of this supplement were adopted from the project proposal and report for a research project supported by the United States Department of Homeland Security, Federal Emergency Management Agency, and Assistance to Firefighters Grants Program [FEMA Grant No.:EMW-2016-FP-00744] and from “Relationship between heat loss indexes and physiological indicators of turnout-related heat strain in mild and hot environments,” by Huipu Gao, A. Shawn Deaton, Roger Barker, Xiaomeng Fang, and Kyle Watson in the International Journal of Occupational Safety and Ergonomics, 29:2, 562-572, DOI:10.1080/10803548.2022.2058746.Link to this article: https://doi.org/10.1080/10803548.2022.2058746Reference to the effect of a walking sweating manikin on heat loss from turnout suits is supported by research described in McQuerry, M.; Barker, R.; DenHartog, E., “Functional Design and Evaluation of Structural Firefighter Turnout Suits for Improved Thermal Comfort: Thermal Manikin and Physiological Modeling.” Clothing and Textiles Research Journal 2018, 36 (3), 165-179.

Original Source: This article is from Fire Engineering. For the full article, visit Systems Tests for Evaluating the Thermal Protective Performance and Heat Strain Contribution of Protective Elements and Ensembles in Structural Firefighter Gear on Fire Engineering’s website.

Recent Posts

Breaking Down CalOSHA PPE Requirements: The Real Deal for Firefighters

Look, we all know PPE is literally what stands between us and disaster on the fireground. But keeping up with CalOSHA requirements can...

Feb 13 • 3 min read

Behind the Scenes: What Really Happens During Advanced PPE Care

Ever wonder what actually happens when your gear goes out for advanced inspection and cleaning? Let's pull back the curtain on what...

Jan 31 • 2 min read

Support

Need Help? We’ve Got You.

At FullBox, we’re here to ensure your experience runs smoothly — whether you're a new user, a growing team, or scaling your operations. If you’re having issues, have questions, or just want to learn more about how FullBox works, this is the right place.

Technical Support

Encountering bugs or issues with your account, dashboard, or integrations?

Our support team is ready to assist.📩 Email us at [email protected]

We typically respond within 24 business hours.

Product Guides & Tutorials

Want to learn how to use FullBox more effectively?Browse our how-to guides, video tutorials, and user manuals for step-by-step support.

Schedule a Personalized Demo

Need a live walkthrough for your team or a specific use case?We offer one-on-one demo sessions to help you unlock the full potential of FullBox.

Submit a Support Ticket

Have a specific problem?Fill out our support request form, and we’ll investigate the issue right away.

Get in Touch

Prefer to reach out directly?Phone: (951) 306-7901

Email: [email protected]

Business Hours: Monday–Friday, 9 AM – 5 PM (PST)

Stay in the Loop

Subscribe to get product updates, new feature releases, and important announcements.